Product Description

Plastic Injection Part Products Characteristic:

1. Well Shape Keeping

2. Deburr, Sharp Edge and Flash

3. Precision Tolerance Control

4. Nice Surface Treatment

5. Colorful Choice

Why Us:

We have a fully-equipped workshop that meets ISO 9001:2015 and IATF 16949:2016 requirements. All products are compliant

with FDA, WRAS, UL, RoHS and REACH standards, and meet DIN, JIS and ASTM regulations. Material report and dimension

checking report are available.

1. Quality Approvals. More than 15 years professional manufacture experience.

2. Experienced Staff and Service. Professional R&D team, production team, sales team, after-sales service team.

3. Product Performance and affordable cost. Superior performance with most competitive price.

4. Prompt Delivery. Faster delivery time.

5. Small Orders Accepted.

| Material | ABS,ASA,PP,PA,PC,PE,POM,PMMA,HDPE,TPE,TPU, PVC,PBT etc |

| Material Report | FDA, ROHS, UL, WRAS and REACH |

| Dimension | Standard Sizes or As per customers’ Requirement |

| Certifications | ISO9001,IATF16949,ISO14001 |

| Color | Any colors according to PANTONE or RAL |

| Surface Finish | Texture (VDI/MT standard, or made to client’s sample), polished (high polish, mirror polish), smooth, painting, powder coating, printing, electroplating etc. |

| Service | Custom Made or OEM and ODM |

| Free Samples | Okay |

| Production Ways | CAD Drawing, 3D Files or Samples |

| Production Capacity | 200T,300T and 500T Compressing Molding, Injection Molding, Auto Vacuum Vulcanizing, Plastic Injection, and Extrusion |

| Supplying Capacity | One Million Pieces/ Month |

| Tolerance | Generally±0.05mm or Better |

| QC | PPAP, In House Control, Third Party Inspection Institution such SGS, TUV |

| Lead Time | 15 Days for Molding, 15-20 Days for Series Production |

| Application | Industry Machinery,Automotive,Mechanical Equipment, Construction, House Application, Medical Machine |

| More Parts |

Grommet, sleeve, feet, gasket, wheel, bellow, cap, dust cover, pad, washer, Strip, plug, stopper, grip, seal, bushing, bumper, blocks, and anti vibration mounts etc. |

FAQ

1. What types of rubber do you use?

Xihu (West Lake) Dis. Rubber has extensive experience in a vast range of rubber, including: Natural Rubber, SBR, CR, NBR, HNBR,

EPDM, Silicone Rubber, FPM, ACM, FK etc.

2. What types of plastic do you use?

Xihu (West Lake) Dis. Rubber has extensive experience in a vast range of plastics, including: ABS, Polypropylene (PP), PVC, POM,

PE, PEEK, Polyamide (PA) Nylons, PBT, etc.

3. What services do you provide?

We offer a broad range of services, including, Custom Rubber Molding, Liquid Injection Molding, Rubber Extrusion, and

Rubber/Plastic to Metal Bonded Parts.

4. Why us?

4.1 More than 15 years professional manufacture experience.

4.2 Professional R&D team, production team, sales team, after-sales service team.

4.3 Superior performance with most competitive price.

4.4 Faster delivery time.

5. Perfect quality control process

5.1 Raw material inspection

All raw materials before warehousing must be tested, and the corresponding physical property report shall be issued,

and compared with the physical property report of raw materials. Only when the test values of the 2 physical property

reports are consistent, can they be warehoused.

5.2 Mold inspection

After mold development or cleaning, we will check the full size of the mold to ensure that the quality of each cavity is

the same.

5.3 Product inspection

In the process of product production, inspectors regularly inspect the semi-finished products to ensure the rationality

of the process and control the defective rate within a reasonable range.

5.4 Finished product inspection

The double inspection can ensure that the product appearance and size are 100% qualified.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | PP |

|---|---|

| Application: | Medical, Household, Electronics, Automotive, Agricultural |

| Certification: | TS16949, RoHS, ISO, Reach |

| Samples: |

US$ 0.05/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the typical power requirements and control methods for power locks?

Power locks typically require a 12-volt power source, commonly derived from the vehicle’s battery. The control methods for power locks include central locking systems, keyless entry systems, and electronic control units. Central locking systems use a centralized mechanism to simultaneously lock or unlock all doors. Keyless entry systems employ remote key fobs that send signals to the vehicle’s electronic control unit, triggering the locking or unlocking of doors. Electronic control units, often part of the vehicle’s overall security system, receive and process signals to actuate the power locks based on user input or predetermined conditions.

editor by Dream 2024-05-09

China high quality Custom PP Plastic Injection Molding Machinery Services Molded Parts for Household Products

Product Description

Custom PP Plastic Injection Molding Machinery Services Molded Parts For Household Products

Product Description

| Product Name: | OEM PP plastic injection molding machinery services molded parts for household products |

| Product No.: | SP06-0003 |

| Shaping Mode: | Plastic injection molding |

| Product Material: | PP |

| Product Dimensions: | 30*30*50mm |

| Product Feature: | Precision dimensions, environmental friendly |

| Product Used for: | Water pipe connector |

| Product Application: | Household, commodity, Industrial, home use |

| Product Type: | Plastic moulding, customized moulding part, injection molding part, machining part, industrial part |

| Product Color: | White, or customised as clients’ requirements |

| Precision Tolerance: | +_0.02mm |

| Product Mould Life: | 100 thousand~300 thousand times |

| Mould Warranty Period: | 1 year or 100 thousand shots(in this period, if the mold have any problem, we will offer the parts or service by free, but it does’t include the problems caused by wrong operation) |

| Ejection system: | Motor/hydraulic cylinder/stripping plate/angle pin, etc…. |

| Cooling system: | Water cooling or Beryllium bronze cooling, etc. |

| Optional plastic materials: | ABS, PPS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PC, PPE, PPO, etc…… |

| Product Mould base: | Standard mould base, LKM, HASCO, DME,etc…… |

| Fast mold design: | We can be within 1-3 working days after getting customer’s drawings. |

| Mould testing: | All of the moulds can be well tested before the shipments. Videos testing the moulds are available. |

| Mould Lead time: | Plastic moulds: 3- 4 weeks after getting the mould design confirmation. |

| Product Minimum order: | Small orders can be accepted. |

| Mould making service: | OEM/ODM service is available. |

| Product Packing: | Opp bag+Carton outside, or as clients’ requirements |

| Mould Safe packing: | In strong wooden pallets to avoid any damages during long transportation. |

| Mould HS Code: | 848571090 |

| Quality System | ISO9001,SGS,TS16949 |

| Specification | Depends on clients’ requirements |

| Origin | HangZhou, China |

Detailed Photos

Similar Products

product/zJrYkjPCJpRW/China-Customised-Design-Auto-Medical-Toy-Household-Electric-Parts-Plastic-Injection-Mould.html

product/eGEpkDRCYfhj/China-High-Quality-Plastic-Injection-Molding-for-Auto-Electric-Control-Plastic-Parts.html

Click here to view more>>>

Company Profile

SENPO PRECISION Tooling Co., Ltd., Foreign Joint Ventures, was established in 2013. It focuses on the application and development of engineering plastics and focuses on high-quality engineering plastics precision parts and precision molds R&D, design and manufacturing, with a number of independent intellectual property rights.

The company’s products focus on passenger cars, commercial vehicles, new energy vehicles, high-end kitchen and bathroom appliances and other fields, providing customers with core components with high safety and important functionality. The product series includes automobile engine peripheral parts, automobile transmission system parts, automobile braking system parts, new energy vehicle parts, household water heater functional parts, household water purifier functional parts, precision industrial parts, etc.

In the context of “replacing steel with plastic”, the company aims to provide products with greater use value, is committed to the localization of high-end precision injection molded parts, and has established long-term and stable cooperative relationships with many internationally companies.

DEVELOPING HangZhouSTONE & HISTORY

|

*2014 Founded YAMANAMI, YAMANAMI was the original company name. *2015 Invested 2 TOPZEN CNC machines for tooling & machining business. *2016 Invested another 2 TOPZEN CNC machines for business increasing. *2017 Invested 2 FANUC high speed CNC machines for tooling business. *2018 Invested 1 SODICK wire cut machine for precision tooling business. |

*2019 Registered SENPO, specializes in global tooling & engineering services. *2571 Invested 1 CROMA CMM measuring machine for precision tooling business. *2571 Invested 3 CHINAMFG mirror EDM machines for precision tooling business. *2571 Invested 3 new injection molding machines for product production business.

*2571 Stop investing and focus on current customer services and developing new clients.

|

**FACTORY EQUIPMENT LIST

|

NAME |

BRAND |

COUNTRY OF ORIGINAL | STROKE | PRECISION | QTY |

| CNC Machine | MAKINO F5 | Japan | 900 * 500 mm | 0.0015mm | 1 |

| CNC Machine | FANUC α-T14iFb | Japan | 600 * 450 mm | 0.005mm | 2 |

| CNC Machine | TOPZEN850 | ZheJiang | 800 * 500 mm | 0.01mm | 2 |

| CNC Machine | TOPZEN650 | ZheJiang | 600 * 500 mm | 0.01mm | 1 |

| CNC Machine | TOPZEN1165 | ZheJiang | 1100 * 650 mm | 0.01mm | 1 |

| EDM Machine | MITSUBISHI | Japan | 400 * 300 mm | 0.002mm | 3 |

| EDM Machine | KYOUMEN | China | 350*250 mm | 0.01mm | 3 |

| EDM Machine | TAIYI | ZheJiang | 650*450 mm | 0.01mm | 1 |

| CMM Measuring Machine | HEXAGON | Sweden | 800 * 600 mm | 0.002mm | 1 |

| Project Measuring Machine | 3D FAMILY | ZheJiang | 300*200 mm | 0.002mm | 1 |

| Height Measuring Instrument | Mitutoyo | Japan | 350 mm | 0.001mm | 1 |

| Wire Cut Machine | SODICK | Japan | 400 * 350 mm | 0.001mm | 1 |

| Grinding Machine | ELITE | Korea | 400* 300 mm | 0.0005mm | 1 |

| Grinding Machine | PENGJING | China | 400* 250 mm | 0.001mm | 2 |

| Milling Machine | TAIYI | ZheJiang | 800* 400 mm | 0.02mm | 2 |

| Injection Machine | HAITIAN | China | 250TON | NA | 2 |

| Injection Machine | SUMITOMO |

Japan |

180TON | NA | 2 |

We mainly provide the following services:

*CNC machining services

*Sheet mental fabrication

*3D printing services

*plastic injection molding

*3D scHangZhou services

*3D design services

*Silicone rubber mold casting services and other rapid prototyping services

Cooperative Enterprises

Our Advantages

| Confidentiality |

|

|

| Initiative communication |

Through many years cooperation with our partners, we are confident to provide you satisfied quality with a reasonable price. Not only providing satisfied quality and on-time delivery, but we also have a dedicated and initiative staff for every issue happened in the process. | |

| Efficient service | For some urgent issues, we provide 7*24 hours for timely feedback.We will reply your mail within 12 hours or earlier since our team members are energetic and all using smartphone devices.Please add our or for better communication. | |

| Advantage in price | We are also happy to follow up your other projects which need outsourcing service, what we think is to save your plant visit cost and transportation cost etc. Our team’s goal is to work hard to find out the best price with good quality products for our customers and achieve more trust and confidence on both sides |

1.Really a one-stop solution for product design, prototype, mold making, injection molding, and assembly.

2.Really a one-stop solution from plastic, silicone, metal, brass, and sheet metal. We work together and focus on the product, saving time on communication.

3.The professional engineering team tracks the project.

4.Competitive price, because we have a great, understanding of different processes and intelligent process management.

Quality warranty:

1. Lifetime sales-after service for all injection moulds.

2. 24Hourse reply on all questions and comments.

3. Mould steel life time quality warranty.(40HRC steel 100K shots warranty, 45HRC steel 1000K shots warranty).

4. CNC machined and prototype according to drawing and 100% size checked before shipment.

5. Material certification, dimension report, checklist for design, mould shipment will send by our engineering team accordingly.

Packaging & Shipping

Delivery time:

**24~48hours for any RFQ

** 3~5days for small qty CNC machined component and prototype

**4 weeks for all injection molds which sizes smaller than 450*450mm

**5~6 weeks for all injection mold which size smaller than 800*800mm

**Samples 4~7days to CHINAMFG by DHL Fedex TNT, etc…

Our Services

|

Product Engineerng Services |

Mold Manufacturing Services |

Product Manufacturing Services |

|

1.Plastic & metal product 3D design support, optimizing. 2.Plastic & metal product engineering DFM, solution. 3.Plastic & metal prototype manufacturing, testing. |

1.Plastic & die casting mold DFM, design, mold flow.

2.Plastic & die casting mold manufacturing. 3.Plastic & die casting mold injection molding. |

1.Plastic & metal part secondary process.

2.Plastic & metal part surface treatment. 3.Plastic & metal product assembly. |

FAQ:

Q1: Are you trading company or manufacturer ?

A1: We are manufacturer, and SENPON Precision Mould is established in 2013 with our own worshop and office

Q2: Where is your factory located?

A2: Our factory is located in Shajing, HangZhou City, ZheJiang Province, China. And it is 20 minutes from HangZhou airport

by taxi directly to our factory.

Q3: How about quality control in your factory?

A3: We believe “Quality is above everything”. We have professional team to control the quality. Our QC team mainly do the following procedures:

A) Design Optimize control

B) Mould steel hardness Inspection

C) Mould assembly Inspection

D) Mould trial report and samples Inspection

E) Final inspection for mould & packing before shipment. If you have another questions, pls feel free to contact us.

Q4: If i provide you 3d drawing of my product, can you quote the price & make the mould as per the 3d drawing?

A4:Yes. DWG, DXF, STEP, IGS and X_T files can all be used to quote price, and making mould as per your drawings can save time and money in producing your parts.

Q5: What type of plastic material is best for my design/component?

A5: Plastic Materials selection depends on the application of your products. We will give you some suggestion after we checked the function of your component. And we can make the trail mould with different materials according to your requirements.

Q6: What kind of moulds can you make?

A6: We can make all kinds of plastic injection moulds. For example:

Household parts mould : Plastic Basket Mould, Plastic Storage Box Mould, Chair &Table Mould, etc…

Appliance parts mould: Fan Mould,Air Conditioner Mould,Washing Machine Mould,TV Mould,Cooler Mould etc….

Automotive parts mould :Bumper Mould, Grill Mould,Interior Parts Mould,etc….

Thin-wall parts mould: Food Container Mould,Ice-Cream Mould, Cup Mould,etc..

Industry parts mould:Plastic Pallet Moulds, Dustbin Moulds,Crate MouldS, Transportation Moulds,etc…

Pipe Fitting Mould: Collapsible Core Elbow Mould, PPR Pipe Fitting Mould,PVC Pipe Fitting Mould, Tee Mould,etc…

We Customized the Plastic Injection Moulds according customers requirements. If you would like to make the Injection Moulds, Welcome! And send us inquiry!

Q7: What about your payment terms?

A7: 50% deposit, and the balance will be paid before shipment.

Q8: How long to finish a mould?

A8: Mostly will be finished in 3~4 weeks, but some complex and big mould will spent more time. According to your order quantity,

the delivery time will be different.

Q9: How long of the mould warranty period?

A9: The mould warranty period is for 1 year(but damage caused by human factors or accident are not included on the scope of warranty), and destroied parts will be supplementary delivered free.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | 2 Years |

|---|---|

| Shaping Mode: | Injection Molding |

| Surface Finish Process: | Texture |

| Mould Cavity: | Single Cavity |

| Plastic Material: | PP |

| Process Combination Type: | Single-Process Mode |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What is the role of power lock materials and coatings in performance and longevity?

The choice of materials and coatings in power locks significantly influences their performance and longevity. High-quality materials, such as stainless steel or reinforced alloys, contribute to the overall durability of power locks, ensuring they can withstand repeated use and environmental conditions.

Coatings play a crucial role in protecting power locks from corrosion, wear, and other forms of damage. Weather-resistant coatings, for example, are essential for outdoor applications to shield the locks from the effects of rain, snow, and UV exposure. Anti-corrosive coatings further enhance longevity, especially in coastal or humid environments where corrosion is a common challenge.

The combination of robust materials and effective coatings not only enhances the aesthetic appeal of power locks but also extends their lifespan, making them more reliable components of security systems over the long term.

editor by Dream 2024-05-07

China Machinery Power Transmission Parts Mechanical Locking Device Power Lock Assemblies how to unlock a car door with power locks

Warranty: 1 calendar year

Relevant Industries: Hotels

Personalized assist: OEM, ODM

Composition: flexible

Standard or Nonstandard: Normal

Substance: Other, 40CrNiMo

Model NO.: SP1 SP2

Type: Locking Unit

Transportation Package deal: Wood Situation

Trademark: SuyeTT

HS Code: 84836 slower about 7-14 times to get there.

What to Do If Your Power Lock Doesn’t Work

Having a power lock is a great way to lock and unlock the doors of your car. The power lock is a lock mechanism that allows the driver or the front passenger to lock or unlock the doors. It is also a great way to secure the car in a parking lot.

Actuator

Having a malfunctioning power lock actuator can cause your door to fail to unlock. This could leave you vulnerable to theft. To prevent this from happening, you should take a look at the components that make up your power door.

First, you’ll want to look at the gears. The gears in your door lock actuator are the ones that allow the motor to spin.

Secondly, you’ll want to look at the switch. This is the component that allows you to turn the lock on and off. If it’s malfunctioning, you’ll probably notice that the lock doesn’t move very much.

Finally, you’ll want to take a look at the solenoid coils. This is the component that provides power to the motor. You can probe these coils with a test light to see if they are working.

It’s not hard to see why this component is a must have. The correct power lock actuator is guaranteed to endure rough road conditions.

If you are experiencing any of the above issues, then you should consider replacing your power lock actuator. It’s not a complicated process, but it’s important to ensure that your power door will function properly. You may also need to replace your entire latch assembly, as well.

You should also take a look at the electrical connector that’s attached to the lock actuator. If you don’t have a test light, you can use an automotive meter to probe the connector to see if there’s power flowing through it.

In the past, it was easy to diagnose a failed power lock actuator. However, it’s no longer that simple. Now, you may need to visit an auto repair shop to have the issue fixed.

Switch

Depending on your vehicle, the power lock switch may be located in the door panel or it may be housed in the armrest area. Either way, the power lock switch can be easily replaced.

The power lock switch, in general, is a simple device that rocks back and forth to lock and unlock your doors. A properly functioning power lock system can control the fuel cap, as well. In some cases, the switch may be integrated into the master power window switch.

The power lock switch may also be located in the center console. A properly functioning switch may make a cool-looking click noise. Some power door lock systems may also include relays to control added actuators.

If the power lock switch isn’t working, the best way to find out is to get it checked out by a professional. A power lock system is one of the most convenient features of a modern car, and it can be frustrating when your door won’t lock or unlock. If it’s not working, you may be able to unlock it by removing the door panel. Depending on your vehicle, it may be worth it to have it checked out by a professional.

Depending on the model you have, you may be required to remove the door panel in order to get to the switch. For some models, the switch may be a single unit. Others may require that you remove the door panel in order to install it.

There are many power lock switches on the market. For example, the CJ Pony Parts switch is a direct-fit replacement that doesn’t require any special tools. The switch has the power to lock and unlock your doors and is available in the driver and passenger side.

Key fob

Unlike traditional keys, which are easy to misplace, key fobs provide a more convenient way to regulate access to your buildings. They can limit access to specific employees or areas. They also allow you to track the number of entries and exits your doors have been opened.

Key fobs are small electronic devices that work with RFID technology. A key fob contains a microchip with a code imprinted on it. The key fob is held in front of an RFID reader, which reads the code on the fob and sends a signal to the fob.

Key fobs are now used by a variety of businesses for security. They have several benefits, including convenience. They are easy to use and can be used in places where traditional keys are not allowed.

Key fobs have come a long way since they were first introduced in 1983. The early key fobs relied on infrared or line of sight. Since then, they have evolved into small, electromagnetic devices.

A key fob’s design allows you to program it for different levels of access. You can limit access to specific employees, areas, or doors. You can also set an audit trail, which can be filtered by door or person.

Key fobs are also able to be copied. For example, your business can have several key fobs. When a new employee joins your company, you will need to get him or her a new key card. This can be time-consuming, especially during temporary furloughs or increased hiring.

While key fobs are convenient, they are also not the best solution for apartment buildings. You may find that tenants lose or misplace their key fobs. Alternatively, you can create a keyless entry system using codes from smartphones.

Diagnosing a problem

Having a power door lock that doesn’t work can be a problem. It can be very stressful, especially when it prevents you from entering your vehicle or locking it up when you get out. If you have a problem with your power lock, there are a few things you can do to try to get it working again.

First of all, try to figure out why the power lock isn’t working. Many common problems can be fixed easily, such as a blown fuse. Blown fuses can be very simple to fix, but you’ll need to know what caused it to blow in the first place.

Another common problem can be a faulty control module. It can be hard to pinpoint the problem with a power door lock actuator, but you can use a test light or automotive meter to find out what’s wrong with it. If the test light shows the voltage is polarized, you can try testing it with a different switch. If the switch doesn’t work, you may need to replace the actuator.

If you have a faulty power lock actuator, you can take it to a local repair shop for a proper diagnosis. They can also provide you with a proper power door lock actuator replacement, if needed. If the problem is not solved, you may want to take it to a dealership, as they can give you a more in-depth diagnosis and advice.

A power door lock actuator that doesn’t work can also mean that there are wiring problems in the door. These may be caused by a frayed wiring harness or a broken door wiring harness.

Repairing a problem

Whenever you have a problem with your power lock, you may need to get the help of an auto mechanic. This is because the lock is not functioning properly and you will not be able to get in or out of your car. There are different things you can do to repair your problem. But first, you should know what the problem is. Here are some of the main reasons why the lock isn’t working.

The most obvious reason why your power lock isn’t working is if the fuse is blown. You can easily check this by examining the fuse box on your vehicle. There should be a metal squiggle on the front of the fuse box. This is the fuse that is responsible for the power to the door lock actuator.

Another reason why your lock isn’t working is if the latches are stuck. The latches can stick for three main reasons. These include a jammed latch, misaligned strike plates and a broken internal mechanism. Changing these parts will fix the problem.

Another thing to check is the spring-loaded pin, which is part of the latch mechanism. This spring-loaded pin should be able to push into the channel of the sprocket. You can replace this part if it is damaged. You can also clean it to get rid of the stickiness. This will also make your power lock work better.

Lastly, check to see if there are any corroded wires that could be causing the problem. If there is, you might need to replace them.

editor by czh 2023-03-24

China Textile Machinery Transmission Parts Z9-100X145 Power Lock best power lock conversion kit

Item Description

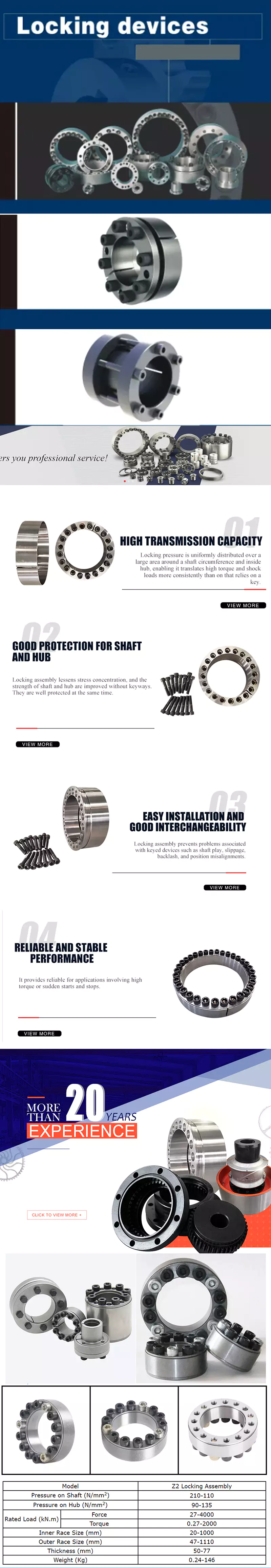

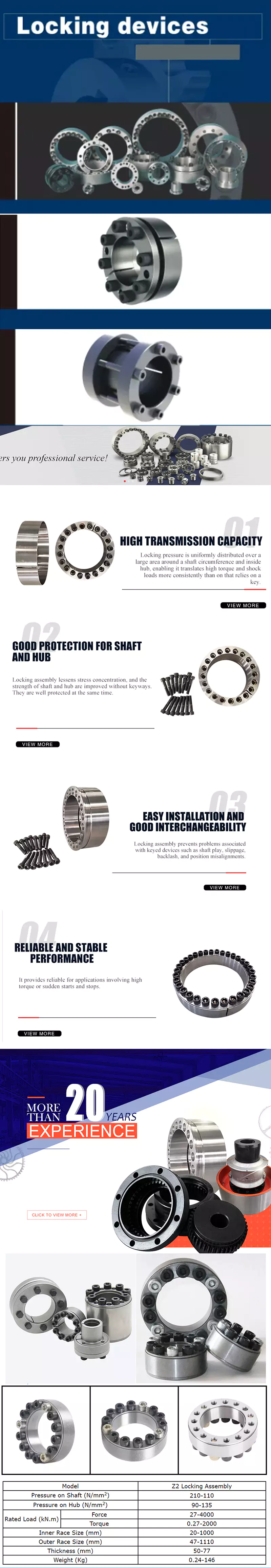

Description of Z9 Locking Device

The primary goal of the growth sleeve is to substitute the operate of splines and single keys, so as to recognize the relationship between the areas (this kind of as gears, flywheels, pulleys, and so on.) and the shaft to transmit the load.

When it is utilised, via the motion of high-strength bolts, a enormous keeping drive is generated in between the interior ring and the shaft, and among the outer ring and the hub. When under load, torque, axial drive, or the mixed load of the 2 is transmitted by the combined force of the enlargement sleeve and the areas and the accompanying frictional power.

Parameter of Z9 Locking Unit

|

US $5-35 / Set | |

1 Set (Min. Order) |

###

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Packaging Machinery, Motorcycle, Food Machinery, Mining Equipment, Agricultural Machinery |

| Material: | Bearing Steel |

| Product Name: | Z9-100X145 Locking Assembly |

| Type: | Z9-100X145 |

| Inner Size(mm): | 100 |

###

| Customization: |

Available

|

|---|

|

US $5-35 / Set | |

1 Set (Min. Order) |

###

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Packaging Machinery, Motorcycle, Food Machinery, Mining Equipment, Agricultural Machinery |

| Material: | Bearing Steel |

| Product Name: | Z9-100X145 Locking Assembly |

| Type: | Z9-100X145 |

| Inner Size(mm): | 100 |

###

| Customization: |

Available

|

|---|

Symptoms of a Bad Actuator in Power Locks

Having a power lock in your vehicle is a great way to keep your doors locked while you’re driving. A power lock allows you to lock your doors from the front or the driver’s seat. The front passenger can also lock their doors from the power lock.

Common uses for power locks

Almost every car model has a power door lock as an option. They can be used to secure high priority areas and to provide an additional layer of security. These locks can be set up to unlock or lock automatically at certain times of the day.

They are also great for business settings, where they can ensure automatic locking after business hours. They can also send virtual keys to guests. This allows them to unlock the doors without having to physically come into the building.

The most common material used to make locks is stainless steel. This material offers excellent corrosion resistance. It also provides great durability. Stainless steel locks are available in a variety of grades, including austenitic grades, which are non-magnetic.

There are also magnetic locks. These are used with access control systems and biometric systems. They are activated by proximity devices, and are used in places where security is a high priority. Magnetic locks are easy to install and can withstand up to 1200 pounds of force.

These are the most common types of power locks. These locks are installed in residential and commercial settings. They may be subject to state and federal regulations, depending on where they are used. They are also used in storage rooms and other high traffic areas.

These locks can be configured for multiple users. These locks are ideal for businesses that want to ensure that only authorized users can open the doors. They are also great for businesses that want to ensure that doors are secured during business hours.

These locks are a great way to increase security in high traffic areas. They are easy to install and require less maintenance than electric strikes. They are also more affordable to purchase than magnetic security locks.

Signs that something is wrong

Unless you’re the proud owner of a power lock, you’re probably not as lucky as a powerless slumdog or two. The good news is that you can remedy your plight with a battery powered power pack and an open mind. Using the aforementioned power pack will allow you to get your power on without compromising your security. The best part is that the power pack will be fully charged by the time you return from your evening stroll.

The most difficult part of this task is making sure that your prized possession isn’t stolen by a ne’er-bee. To avoid such a mishap, it may be prudent to install a security system such as a monitored door lock. Besides, the power packed power pack can also act as a shield from unseen intruders. With a power packed power pack on hand, the worst that can happen is that you can be locked out of your own home. That’s a good reason to do your research. Fortunately, your power packed power pack can also act as your best friend. After all, who has the time to deal with a burglar? Having a properly installed power pack can save you the embarrassment of a lockout. Having the right power pack on hand is a great start, but you may want to do some homework before you go to bed. A properly installed power pack should be the foundation of any security system. After all, your home is one of the most valuable things in your possession and you should treat it with the same level of respect as you would treat your dog or children. For a small fee, a reputable security service provider can help you maintain a home that you can be proud of.

Symptoms of a bad actuator

Symptoms of a bad actuator in power locks are not always visible. This is because there are many factors that can cause them to malfunction. A faulty actuator will not only cause the door to lock, but it will also lock and unlock in an unpredictably random manner.

The best way to find out if your power locks are malfunctioning is to first check the power to your actuator. This will not require too much effort. You can either connect a jumper wire or use a power probe to apply 12 volts to the actuator.

If you don’t have access to a power probe, you can use a small screwdriver to turn the lock handle up and down. You can also use a coat hanger to unlock the door.

The most obvious symptom of a bad actuator in power locks is the ability to lock or unlock the doors of your car. However, there are other signs as well. For instance, you may notice that the interior lights stay on when the doors are closed. This is a sign of a broken wiring harness.

If you have a car with more than two wires, you should consult your car’s wiring diagram. If your car’s locking system is malfunctioning, you should try a replacement door lock actuator.

Other symptoms of a bad actuator in power locks include strange noises when the door is opened. This can also be a sign of a broken door panel connection. This is not necessarily a problem, but it is a good idea to check it out before replacing your entire door lock assembly.

If your car is a newer model, you may need to disassemble the door lock assembly to access the actuator. If you’re not comfortable with that, you can always hire a third party mechanic to do the job.

Diagnosing a bad actuator

Getting a bad actuator for your power lock can cause your doors to lock or unlock randomly. Symptoms include the door lock working perfectly one day, then not working at all the next. You may also hear weird noises when the door lock is operated.

The first thing you need to do is check the power supply to the actuator. This can be done by using a Power Probe. The Power Probe has jumper wires that can be used to apply 12 volts to the actuator.

Once you have a good power supply, you can remove the actuator. Most actuators can be removed with your hands. Before removing the actuator, make sure that it is mounted properly and that it does not bind.

If you are still having trouble, you may have to replace the whole latch assembly. This is a fairly simple and inexpensive process. If you are unsure of how to do this, you may want to call a mechanic. They will be able to help you diagnose your power lock.

If you have a door lock that makes a clicking sound, you may have a bad actuator. If the clicking sound is not consistent, you may have a problem with the door lock switch. You can try to replace the fuse. If that doesn’t work, you may have a broken connection between the door panel and the actuator. You can also try to remove the door panel and check the solenoid coils.

A broken or dirty lock assembly can also cause the door to lock or unlock erratically. If the lock has a problem with its sensor, the car may stop locking and unlocking at certain speeds.

Repairing a bad actuator

Having a problem with your power lock actuator can be a real hassle. You may hear strange sounds or see your car’s doors lock or unlock erratically. This type of problem can be caused by a number of factors.

First, a good diagnostic test can help you determine if the issue is with your power lock actuator or a related component. The first thing to check is the voltage polarity at the electrical connector. This can be done with a test light or automotive meter.

Another way to test the voltage polarity is to disconnect the electrical connector. This will allow you to take the actuator and lock assembly off. If your door locks are working properly, you will see a positive reading on both sides of the connector. If you see a negative reading on one side, this is an indication that the actuator is not working.

If you don’t have a test light or automotive meter, you can use jumper wires to apply 12 volts to the actuator. You may have to remove your outer door handle to access the wires.

If your door locks are not working, you may need to replace the door lock actuator. It is recommended that you replace the actuator once or twice in your car’s lifetime. This will make your vehicle easier to use and more convenient.

Identifying the problem is the first step in the repair process. If you are unable to find the problem, you may need to replace the entire lock assembly. Some cars may also require the window regulator to be removed.

Once you have determined the problem, you can either troubleshoot your power lock system or replace the entire latch assembly. This will be expensive, however.

editor by czh 2022-12-23

china near me shop Textile Machinery Transmission Parts Z7d-40X75 Power Lock manufacturers

Solution Description

Description of Z7D Locking Device

The primary function of the expansion sleeve is to exchange the function of splines and solitary keys, so as to comprehend the connection amongst the elements (this sort of as gears, flywheels, pulleys, etc.) and the shaft to transmit the load.

When it is employed, through the action of higher-toughness bolts, a massive keeping pressure is generated amongst the interior ring and the shaft, and among the outer ring and the hub. When below load, torque, axial force, or the combined load of the two is transmitted by the combined stress of the expansion sleeve and the parts and the accompanying frictional power.

Parameter of Z7D Locking Device